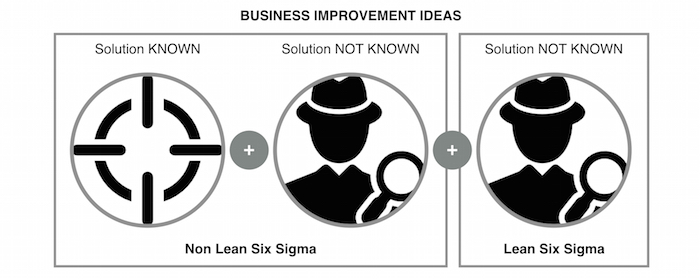

Notice the existing business improvement system is not eliminated ... it's actually ENHANCED by the INCLUSION of Lean and Six Sigma methods.

So what about business improvement project identification?If you're going to undertake a formal business improvement initiative, then use a project selection approach that has GENERIC application in that it's suitable for companies utilising a range of business improvement methodologies such as:

Six Sigma,

Lean Manufacturing,

Design for Six Sigma,

QFD

Theory of Constraints .....etc

The step of IDENTIFYING business improvement project ideas is a critical one in the sequence as it sets the initiative up for either success or failure.

More Than One Way to Skin a CatWe don't want to take an approach quite so unsophisticated as just asking 'What do we need to do to improve our business?' Let's inject some science and strategy in the way we tackle the question of where and how to improve our businesses.

Some of the more robust scientific ways are these:

Waste Walks

Problem or performance gap identification

Problem or performance gap creation

Business driver analysis

Analysis of processes for constraints

Analysis of performance against customer expectations or any other key business measures

Opportunities can and should be identified by taking a look at the business from a variety of angles.

Why There Isn't The ONE WayFirstly, let's acknowledge that all businesses differ; no two are exactly the same.

The way in which a business identifies opportunities for growth in value will be driven by many factors including maturity, market forces, operating methods and culture.

Secondly, business and operating thinking patterns vary so greatly that no single approach is best.

Source: This article is adapted from Process Alchemy (with Lean Six Sigma) 2nd Edition, available from the

9 Skills Factory bookstore.